This content highlights the advantages of switching from rigid plastic containers to Whirl-Pak® Bags in the sample collecting and storage process. The benefits include a significant reduction in plastic media waste, greenhouse gas emissions, water usage in manufacturing, overall hands-on time, and storage space. Additional advantages encompass lower shipping and disposal costs, along with puncture-proof, leak-proof closure tabs, guaranteed sterility, and easy identification. The information is backed by a case study conducted in April 2022 by Nasco Sampling LLC. The content also provides a step-by-step guide for implementing the switch, addressing considerations such as raw material and finished product testing, informing purchasing and disposal services, capturing team concerns, and setting up product and testing stations. The Whirl-Pak® Bags meet federal regulations and comply with standards set by FDA, USDA, HACCP, and EPA. For further information or assistance in transitioning to Whirl-Pak® Bags, readers are encouraged to contact the Product Specialists.

Benefits of Converting to Whirl-Pak® Bags

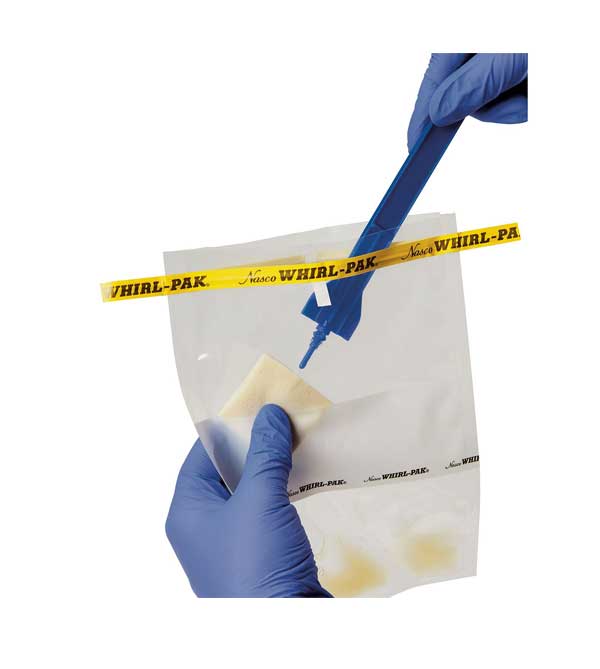

Incorporating sample bags into your sample collecting and storage process has many advantages that benefit not just your bottom line but the environment as well. Sustainably and effectively collecting and storing samples across many applications has been shown to be attainable. Below are the main reasons why you should consider implementing these changes today.

Top benefits include:

- Reduce plastic media waste by 95%.*

- Reduce GHG emissions.*

- Reduce water in the manufacturing process.*

- Reduce overall hands-on-time by 76%.*

- Reduce storage space.

- Lower shipping costs.

- Save on disposal cost.

- Puncture-proof, leak-proof closure tabs.

- Guaranteed sterility.

- Easy identification.

*Case study: April 2022 - Nasco Sampling LLC.

Implementing the Switch to Whirl-Pak® Bags:

Not sure where to begin with implementing this whole new system into your daily process? Proper installation and implementation is critical to the success of your process. Following these steps will help serve as your guide to the best possible solution to your implementation pain points.

Step 1—Map out a list of raw material and finished product testing.

• List your current inventory of bottles or bag sizes.

Step 2—Inform purchasing and services of charge.

• Provide a Whirl-Pak product list to your purchasing agent.

• Notify disposal services of changes—frequency and volume will be reduced.

Step 3—Meet with your teams to capture concerns.

• Potential questions might include: Will this take more time? How does this impact other portions of my job? We've always done it this way, why change now?

Step 4—Set up product and testing stations.

• Troubleshooting with your team to address challenges before full implementation.

Federal regulations met: R-Nase, D-Nase, Pyrogen and BPH free and complies with FDA, USDA, HACCP, and EPA.

For assistance in making the switch to Whirl-Pak® Bags, contact our Product Specialists today!